All Semperit tyres which can be regrooved have on both sidewalls, in accordance with ECE regulation 54, the word REGROOVABLE

The additional tread depth of up to 4 mm gained by regrooving means a significant increase in performance.

As part of their design, all-steel truck tyres have a so-calles tread stock between the upper edge of the belt and the tread grooves. This tread stock is intended to prevent stones etc. penetrating into the steel belt and the casing.

Provided it is marked "REGROOVABLE", a commercial vehicle tyre may be regrooved down to a residual undertread thickness of 2 mm above the breaker or belt. All additional regulations of the respective country must be met.

Although tyres can be remoulded after reaching the legal wear limit, regrooving is not advisable in every case. The tread stock thickness is reduced and stones etc. can more easily penetrate and damage the steel belts, leading to rust formation. This has a decidedly negative effect on the tyre's suitability for retreading.

The best time for remoulding is when the tread is worn down to about 3 mm. The tyre must then be checked to make sure the wear is even all round. Attention should be paid to local or uneven wear patches.

Regrooving should be carried out by a qualified expert, in order to avoid premature failure as well as any reduction in the tyre's suitability for remoulding.

In some countries (e.g. Germany for KOM-100 coaches and Austria for coaches) regrooving of front axle tires for coaches is prohibited. In general, regrooving on front axle coach tyres is not recommended.

All Matador tyres on which regrooving is permitted are marked "Regroovable".

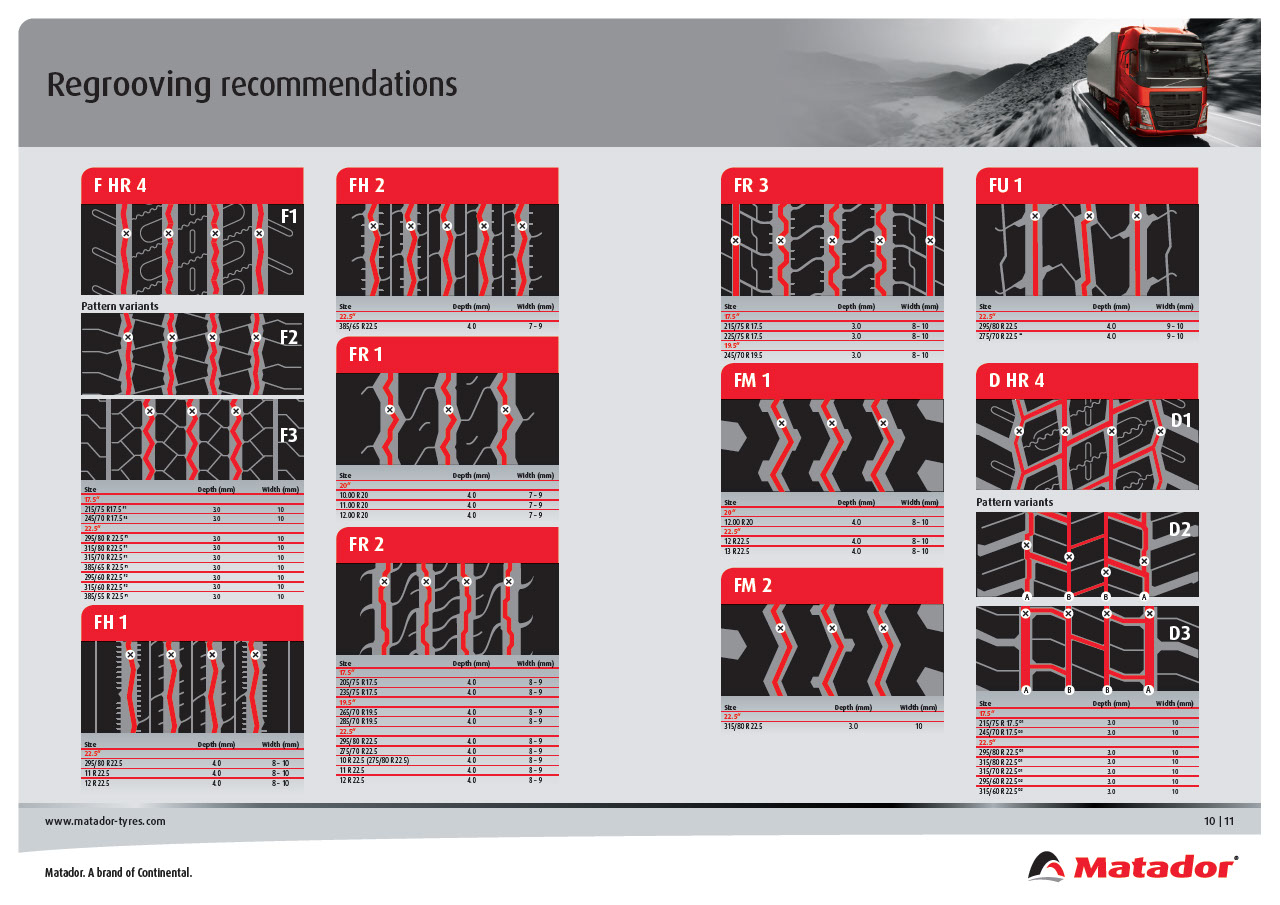

Matador Truck and Bus tyres Regrooving Recommendations

Matador Truck and Bus tyres Regrooving Recommendations

pdf 341 KB DownloadRelated topics

-

2024/10/30Winter regulationsEuropean regulations for winter equipment on trucks and buses.Read more

2024/10/30Winter regulationsEuropean regulations for winter equipment on trucks and buses.Read more -

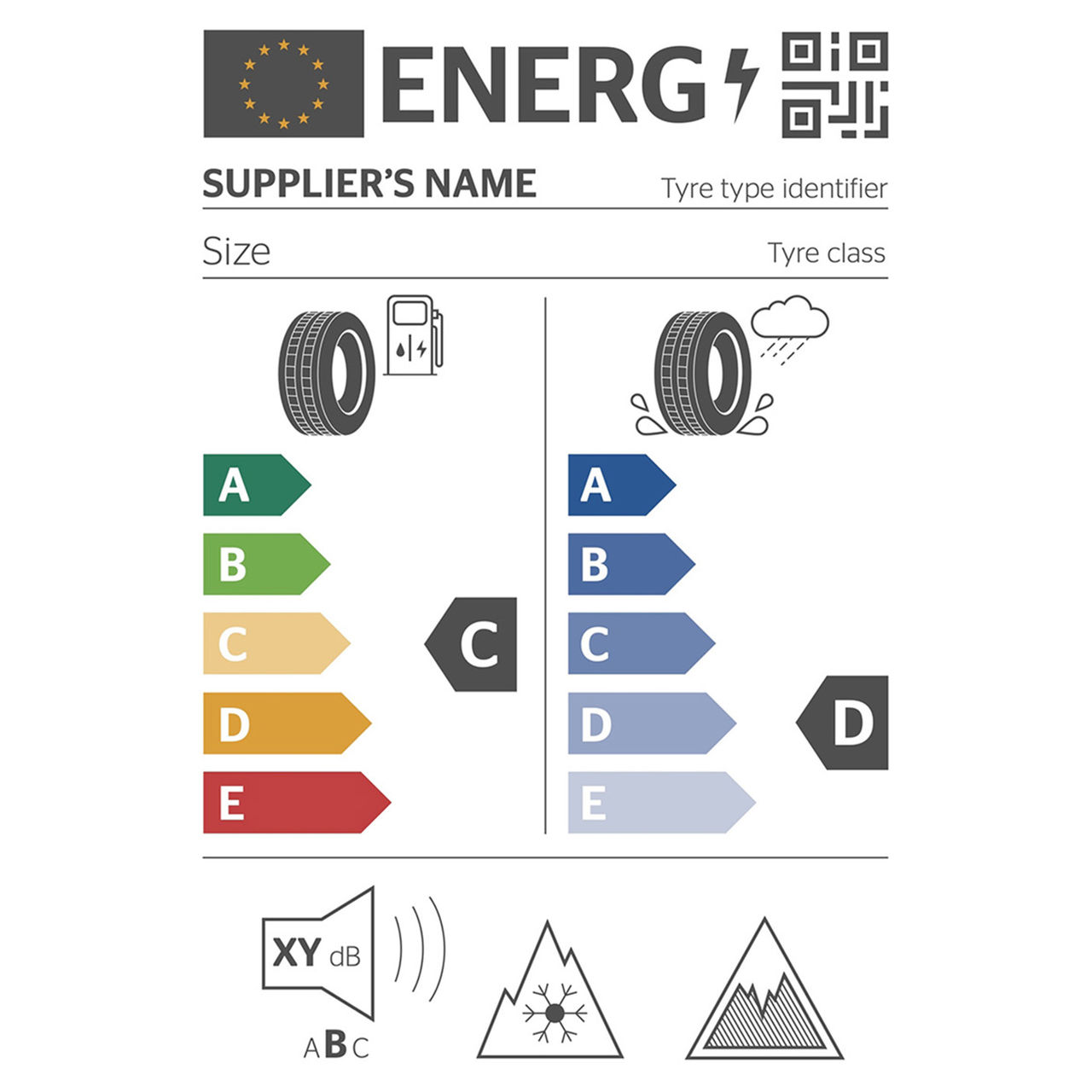

2024/04/24EU Tyre LabelBased on three criteria, the EU Tyre Label provides information on the environmental and safety characteristics of a tyre.Read more

2024/04/24EU Tyre LabelBased on three criteria, the EU Tyre Label provides information on the environmental and safety characteristics of a tyre.Read more